Power. Precision. Proficient.

Our Features

Exceptional Quality

Committed to excellence, we adhere to stringent quality standards at every production stage.

Global Reach

With a global presence, we serve customers worldwide, offering local support and expertise.

Industry Expertise

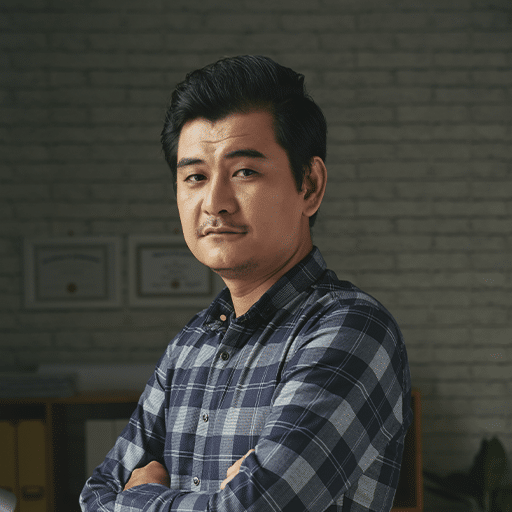

With years of industry experience, our team of experts brings unique expertise and knowledge.

About SAME Waterjet the Industry Leader

Embrace the Future of Technology With Us

Bring The Future For The Technology Companies

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes.

Diverse Material Cutting Expertise

Metal

Stone

Porcelain

Glass

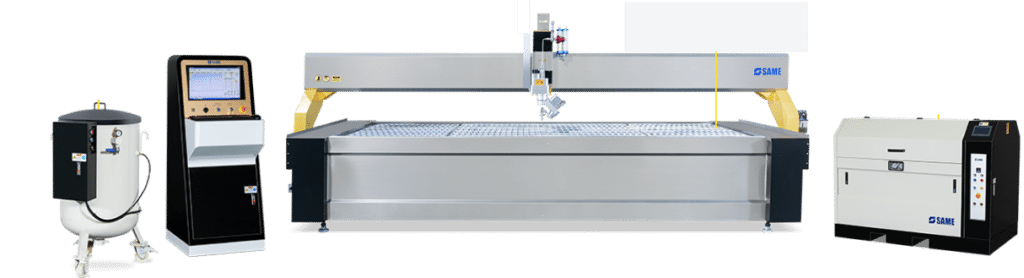

5-Axis Cutting Machine from SAME Waterjets

This reliable and precise system ensures consistent dosing of abrasives for optimal cutting efficiency and accuracy.

Designed for efficiency and accuracy, this system empowers you to achieve superior results in your machining operations.

Engineered for intricate cuts and complex shapes, this cutting head enables you to expand your capabilities.

Engineered for stability and precision, this table provides a reliable platform for your waterjet cutting needs.

Built for reliability and performance, this essential component delivers the high-pressure water necessary for cutting.

This reliable and precise system ensures consistent dosing of abrasives for optimal cutting efficiency and accuracy. 1 of 5

Designed for efficiency and accuracy, this system empowers you to achieve superior results in your machining operations. 2 of 5

Engineered for intricate cuts and complex shapes, this cutting head enables you to expand your capabilities. 3 of 5

Engineered for stability and precision, this table provides a reliable platform for your waterjet cutting needs. 4 of 5

Built for reliability and performance, this essential component delivers the high-pressure water necessary for cutting. 5 of 5

SAME Waterjet Cutting Services

State-of-the-Art Factory & Equipment

Voices of Satisfaction

Thank you

We purchased our SAME waterjet about 2 years ago and are very happy with it.

We got this machine to replace our OMAX Maxiem machine purchased from Headland Machinery. We had nothing but trouble from the start with our OMAX machine and had an overall disappointing experience with Headland. The OMAX would constantly breakdown and the design of the machine was very complicated for nothing. If a high-pressure hose went in the 5-axis head it would take a whole day for a technician to fix the machine. I have many examples and stories of how much I hate the OMAX machine and dealing with Headland (who would always not have parts on hand) so I won't bore you with anymore details. We finally scrapped that machine and it was a very happy day for me.

The SAME machine on the other hand I've found is well designed in comparison and easy to repair. The SAME machine is easy to operate and robust. We have cut many materials with it including 6 inch Titanium billets. A very capably easy to use machine. They always have parts that you will get next day (From Sydney to Melbourne). They are very friendly and accommodating. We are very happy with our purchase.